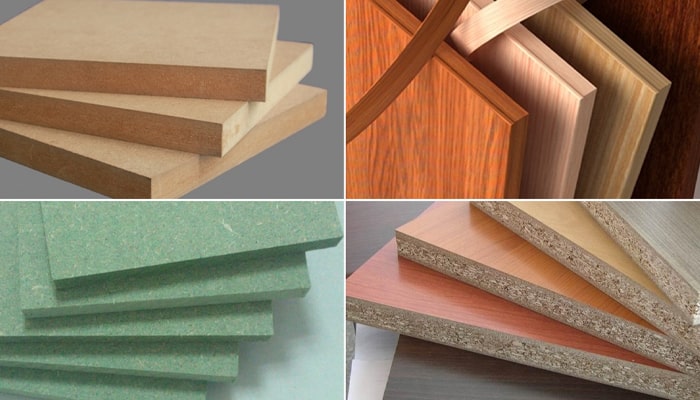

Arcade Cabinet MDF vs Plywood are two strong industrial woods, popular and widely used in furniture production today. Answering this question can help you make the right choice. While both are engineered wood products, they have their own pros and cons.

What might make one your superior choice depends on the advantages and disadvantages it offers you. So, let’s break down their properties and features and conclude which plywood and MDF are the best.

1. Concept

1.1. What is Arcade Cabinet MDF?

The term MDF stands for Medium density fiberboard, which means medium density fiberboard. But in reality, MDF is the common name for all three types of fiberboard products with medium density and high density (hardboard).

To distinguish these three types, people rely on physical and mechanical parameters, parameters of thickness, and surface treatment of the board.

In terms of structure, the MDF board has the basic components that are: wood fiber powder, adhesive, paraffin wax, wood protection agent (anti-termite, anti-mold), and inorganic filler powder.

Dry process: glue, and additives are sprayed into the dry wood pulp in a pre-drying mixer. The glued fiber powder will be spread out by a spreader-scraper into 2-3 layers depending on the size and thickness of the manufactured plywood. These floors are passed through a heated press.

The first time (preliminary pressing) for the upper layer, the second layer, and the third layer. The second pressing time is to press all three layers again. The heat setting is set so as to expel the steam and slowly solidify the glue. After pressing, the board is exported, edges removed, sanded, and graded.

Wet process: wood pulp is wetted with water to form a mat formation. They are raked and then spread on the press plate.

Heat press once to preliminary thickness. The sheet is passed through a steam-heat lamination like a paper-making side to compact the two sides and draw out excess water.

1.2. What is Plywood?

Plywood is that it’s a sheet material that is brought to life by combining layers of wood veneer, which are glued together. Each adjoining layer is rotated up to 90 degrees in a process we call cross-graining. Why is this done? Well, the major reason is that it gives the product super strength.

Thanks to cross-graining Plywood is able to resist splitting when nailed at the edges, minimize expansion and shrinkage and bump up its stability. Similarly, when cross-graining an odd number of layers will be used. This provides us with a balanced sheet that won’t easily warp.

The core layers are also crucial to the strength of Plywood. These layers increase the separation between the outer layers where stress is at its highest, meaning its ability to fight back against bending is raised dramatically.

Thanks to this method of design larger sheets of Plywood can be created while still handling similar loads by increasing the thickness. However, it’s also perfect for smaller-sized sheets too.

Here at Plyco, we love our nifty Quadro range of Birch Premium Plywood products, which come in a smaller 1200mm x 600mm panel. Because Plywood doesn’t lose any of its effectiveness or quality in smaller sizes it means we can offer a convenient solution for those who want Plywood delivered to their door!

2. Difference between Arcade Cabinet MDF and Plywood

2.1. How They’re Built

The main composition of MDF includes: about 75% of raw materials are made from natural wood, 10-15% of adhesives, 5-10% of water and less than 1% are other additives such as: hardener, wood protectant against termites, scratches, paraffin…

Plywood panels are fabricated from multiple layers or plys of softwood veneer glued together with the grain direction of each layer of veneer perpendicular to that of the adjacent layers.

These cross-laminated sheets of wood veneers are fastened together with a waterproof phenol-formaldehyde resin adhesive and cured under heat and pressure. In BC, plywood is made from softwood species, usually Douglas-fir or spruce, pine and fir (collectively known as Canadian softwood plywood-or CSP).

The most common dimension is 4 feet × 8 feet. Plywood varies in thickness, the most common being ½-inch.There is a wide variety of choices when it comes to plywood, ranging from smooth, natural surfaces suitable for finish work to more economical unsanded grades used for sheathing.

2.2. Moisture Resistance

- Plywood: will be more waterproof and water-resistant than MDF.

- MDF: can absorb water and other liquids such as sponges and is easily damaged by prolonged exposure to water.

2.3. Shock resistance

- Plywood: The impact resistance of plywood is high and it can withstand short-term overload.

- MDF: not as hard as plywood and therefore its impact resistance is lower than plywood.

2.4. Warping and cracking

- Plywood: With reduced expansion and shrinkage, plywood shows higher resistance to warping and cracking.

- MDF: As MDF expands and contracts in response to fluctuations in temperature and humidity, it will warp and crack.

2.5. Weight

- Plywood: Plywood is light in weight when compared to MDF.

- MDF: is a dense material and therefore it is heavy.

2.6. Sawing and cutting

- Plywood: It is not easy to cut and carve designs from Plywood because of its thin nature.

- MDF: Since MDF is not hard, it can be cut easily.

MDF generates more dust when cut. Due to its construction, MDF produces more sawdust when cut than plywood, so you will need to exercise extreme caution when working in a well-ventilated area and wearing a respirator or face mask and glasses. other protection.

MDF is easy to cut, even along the edges. Are you planning to make a piece of furniture, frame or cabinet door with ornate roll decoration?

Then you’ll be happiest with MDF. Because of its grain-free and softness, MDF is easy to cut and won’t crumble or crack along the edges, even if you carve in curves, sharp corners or ridges.

In contrast, due to the stacked texture, the edges of the plywood are rough and unsuitable for intricate curves or cuts. Even straight cuts can cause edges to tear, but our plywood cutting tips can help you eliminate those imperfections.

2.7. Durability and strength

- Plywood: Due to its cross-layer construction, Plywood is very strong and durable.

- MDF: MDF is not as strong and durable as Plywood.

When it comes to strength, plywood is always on top. MDF is a softer material than plywood and tends to sag or split under pressure. That’s why it’s important to reinforce it if you’re going to use it to close shelves or other weight-bearing furniture.

Plywood is also more flexible than MDF so you can bend it slightly to create curves; In addition, plywood will not expand, shrink or warp, even under extreme temperatures. Plywood and MDF have always had different strengths for the different uses they create.

2.8. Painted plywood and MDF

MDF is great for painting, while plywood is great for stains. This is one of the key questions when weighing MDF versus plywood: Are you planning on repainting the finished project or staining it?

MDF, with its smooth and grain-free surface, paints like a champ, although for the best finish, start with an oil-based primer. While you can paint plywood, higher grade plywood looks great in the presence of stains, due to its wood-like surface and grain.

2.9. Cost

- Plywood: Plywood is expensive and its price increases as its grade increases.

- MDF: MDF is generally less expensive when compared to Plywood.

In general, MDF is cheaper than plywood. Although the price depends on the thickness and grade of the material, in general, MDF costs less than plywood.

If no other factor drives you to one material over another and you are observing the bottom line, then MDF wins the price war.

Plywood looks more like real wood. Since plywood is made of strips of wood, its surface has a better solid wood-like appearance than MDF.

The more advanced grades of plywood are smooth and quite attractive, with plenty of grain, but none of the grain that would damage the solid wood. In contrast, MDF has no grain, is not as smooth as plywood, and looks just like what it is wood fiber.

3. A1 Plywood – Prestigious and quality Plywood factory

A1 Plywood is committed to the prestige and quality of products, ensuring that Plywood panels are always delivered to customers according to requirements and designs.

We own a direct furniture factory in Vietnam, with a team of skilled carpenters; each product is made carefully from the stage of choosing boards to construction and installation.

The factory accepts orders to produce Plywood boards based on the correct sizes and measurements as required, and delivery on time.

The above is the differences between Arcade Cabinet MDF and Plywood, basing on it customer can choose the suitable wood.

Related keywords: arcade cabinet mdf vs plywood, mdf thickness for arcade cabinet, arcade cabinet wood, wood arcade cabinet