Nowadays, there are many types of industrial wood materials used to make wooden furniture in homes or offices. However, one of the prominent names mentioned in recent times and won the hearts of many users is Plywood. In this article, let us learn about the advantages and disadvantages of Plywood with A1 Plywood!

1. Structure, characteristics

1.1. Structure

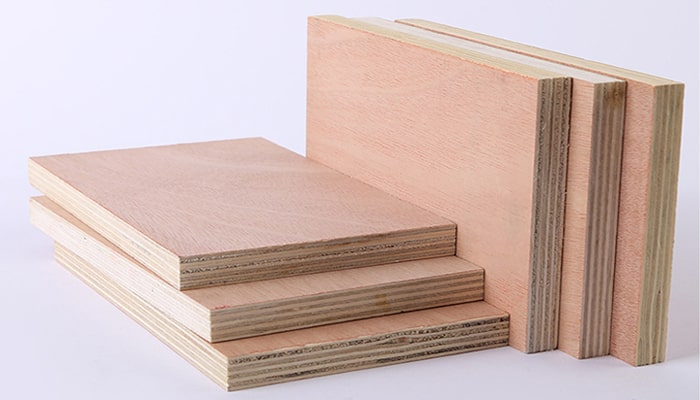

- The core: consists of many thin layers of wood with a thickness of about 1 mm.

- The surface part: is a layer of natural wood.

- Glue part: commonly used glues for plywood are Urea Formaldehyde (UF) glue and Phenol-Formaldehyde (PF) glue.

1.2. Characteristic

- Good bearing capacity, less deformation, termite warping, good moisture resistance, used in environments with high humidity.

- The average density of plywood is 600 – 700 kg/m3.

- Common plywood size: 1220 x 2440 mm; 1160 x 2440 mm; 1000 x 2000 mm.

- Common plywood thickness: 3, 4, 5, 6, 8, 10, 12, 15, 18, 20, 25 (mm).

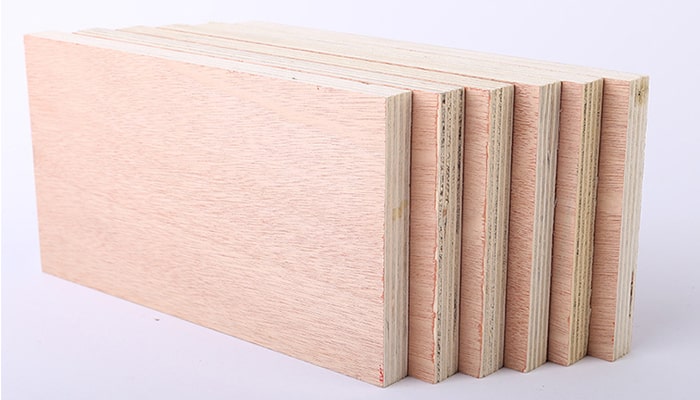

- The layers of a plywood board are always odd (3, 5, 7, 9…) so that the board has a core layer in the middle, to create the same grain direction in the two outer layers of the core layer and help the These layers of wood restrain each other from warping or cracking.

- The grain direction of the outer layers will be arranged perpendicularly to increase the bearing capacity as well as prevent the warping and cracking of the wood.

2. Advantages of Plywood

2.1. High hardness and durability

- Experiencing glue spraying and heat pressing many times, plywood is considered by experts to have relatively high hardness and durability.

- With modern production technologies, Plywood wood is tested and evaluated for its durability and elasticity through every step, each production stage is very meticulous.

2.2. More water-resistant than MDF

- Plywood wood is one of the industrial wood products with good moisture resistance and resistance to water penetration.

- When dropped into the water, plywood is not as easily swelled as MDF.

2.3. Faster sanding and PU coating time

- The surface of Plywood is quite smooth, especially the wood that goes through the production stages to help own a smooth surface that is easy to perform decorative steps such as sanding or applying Pu paint on top.

- Has good screw and adhesion ability.

- The price of plywood is much more reasonable than that of rare natural woods.

- Suitable for modern interior spaces, it is very popular today, especially for young families.

3. Disadvantages of Plywood

3.1. Plywood has a higher cost than MDF, MFC

- Plywood has a higher cost than MDF or MFC because of its high water resistance and moisture resistance as well as a smooth surface.

3.2. Plywood edge is prone to chipping

- Plywood edges are very susceptible to chipping during cutting or long-term use.

- The user must always wrap the plywood edges, if in the process of using these coatings scratches expose the wooden edges, it is very easy to chip and lose aesthetics.

3.3. Easy to warp, separate layers

- This is very easy to happen to plywood factories that do not meet standards, “eat down” the stage, press wood not according to specifications and standards, or use the wrong type of specialized glue.

- Many errors in the manufacturing process cause plywood to warp, rough surface when exposed to high temperature, or delamination when in a high humidity environment.

3.4. The color is not beautiful with MDF, MFC

- Plywood has uneven colors and textures like MDF or MFC.

- Plywood is not used much in common spaces such as living rooms, and kitchens, but is often used in bedrooms, offices, floors, decorative shelves…

4. Frequently asked questions

4.1. What are the 3 physical properties of Plywood?

- The average density of plywood is 600-700 kg/m3.

- Common plywood size: 1220 x 2440 mm; 1160 x 2440 mm; 1000 x 2000 mm.

- Water absorption is quite good.

4.2. What properties make Plywood strong?

- The number of layers in a piece of plywood determines its strength.

- The thicker the plywood, the stronger it is. One of the most commonly used plywood thicknesses is ¾ inch plywood.

- The type of wood used for plywood makes a difference in its durability.

4.3. What are the advantages of Plywood?

- Has high hardness and durability.

- Water-resistance is better than MDF.

- Has a fast sanding and PU coating time.

4.4. What is the purpose of Plywood?

- Used as formwork for construction, building boats, boats, wooden floors, and partitions.

- Plywood covered with high aesthetics is often used as sofa, wardrobe, bed, desk, etc

5. A1 Plywood – Prestigious and quality Plywood factory

A1 Plywood is committed to the prestige and quality of products, ensuring that Plywood panels are always delivered to customers according to requirements and designs.

We own a direct furniture factory in Vietnam, with a team of skilled carpenters, each product is made carefully from the stage of choosing boards to construction and installation.

The factory accepts orders to produce Plywood boards based on the correct sizes and measurements as required, and delivery on time.